Passionate About Precision

Ohnhäuser GmbH stands for top-quality production – the outcome of decades of experience and of our quality philosophy. An achievement that we repeatedly demonstrate with internal quality indicators taken on a regular basis.

To ensure Ohnhäuser quality, we check all relevant stages of production, including

inspection of incoming goods, inspections during production, interim and transfer inspections, FAIs, and final inspections.

Standardized and targeted inspection instructions are used for every test process. These internal inspection instructions combine all the requirements of EN 9100 and the relevant customer specifications, broken down to the relevant process steps. This is how we can guarantee quality while achieving the best possible cost efficiency.

The Latest Technology and Top-level Know-how

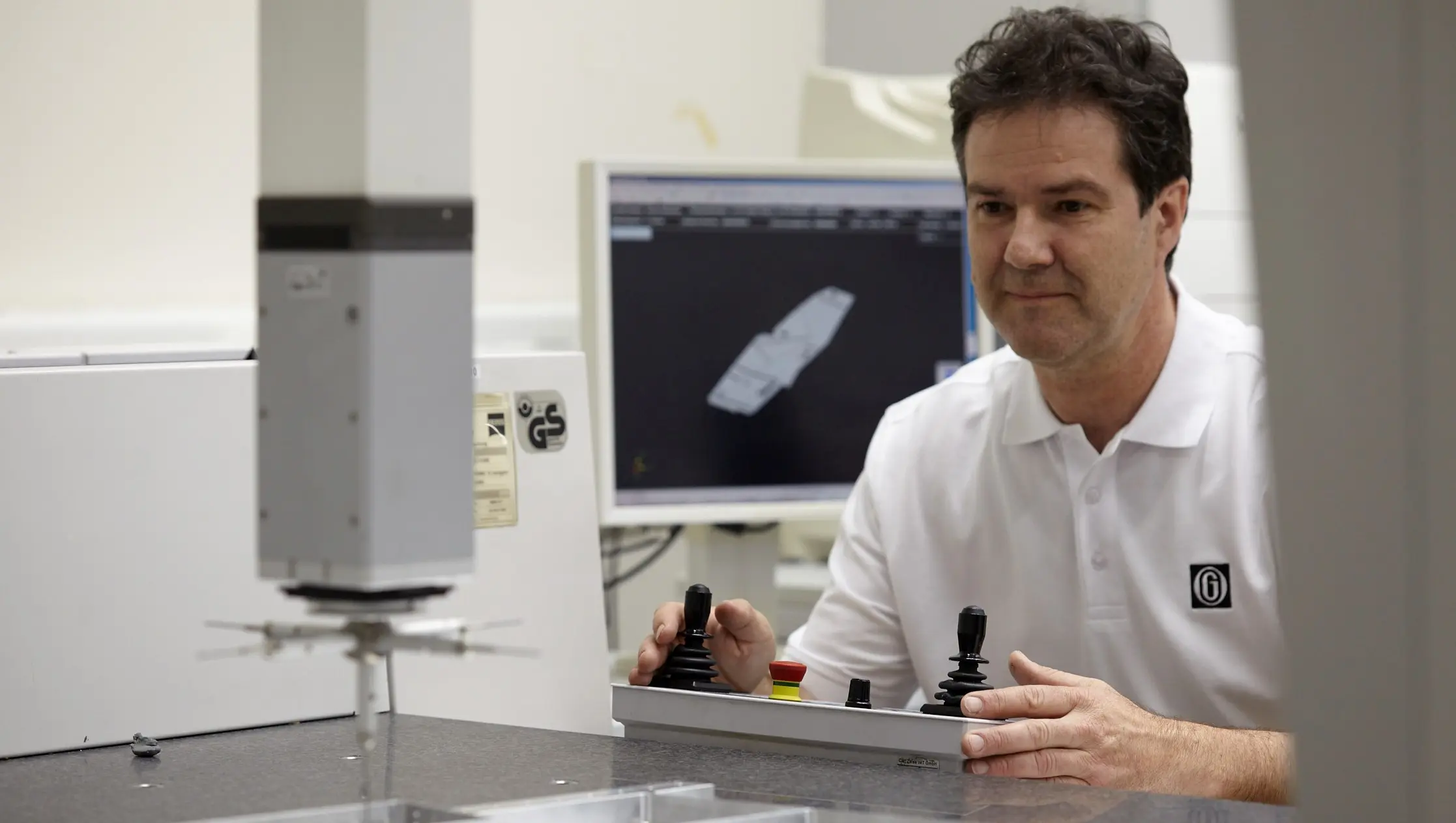

Quality management at Ohnhäuser GmbH is the work of highly qualified staff. Working to a three-shift pattern, they guarantee a high level of efficiency and short throughput times for all inspection processes.

Using the latest technology, such as 3D coordinate measuring machines, gear measuring machines, and spectral analysis methods, we guarantee reliable results with optimal measuring conditions in climate-controlled environments.